| Specifications | Part Number |

|---|---|

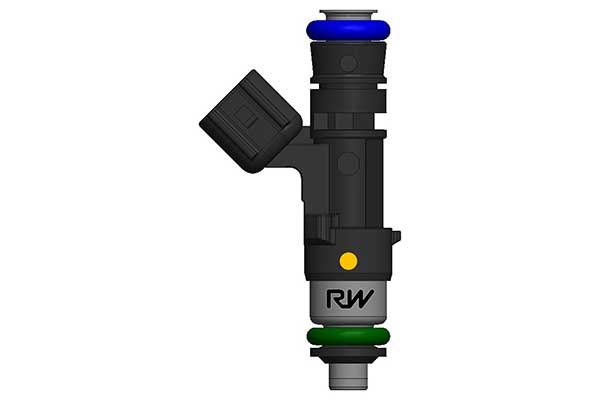

| Modified/High Flowed Bosch Injector Size: 1000cc (95 Lb/hr) @ 3bar and 1150cc (110Lb/hr) @ 4bar. Impedance: High (12 Ohms) Plug: USCAR. Top O-Ring: 14mm. Ethanol & Methanol Safe Spray Pattern – Narrow Cone Spray Direction – Straight Flow variance is +/- 1.5% (3% Total) |

INJ-501 |

Download Injector Calibration Data PDF

Download Injectors Size Charts PDF

*Direct fit applications

Holden Commodore VZ V6

Holden Commodore VE V6 (Excluding SIDI)

*Injectors are a direct fit physically, but as with all Raceworks Injectors, will require a tune. While the vehicles listed above are direct fit, the injector can be used in many other applications with the appropriate extensions, o-rings or plug adapters. See Injector Upgrade Guide for more details.

| Normally Aspirated Gasoline | 185HP | 140KW |

| Forced Inducted Low Boost Gasoline | 155HP | 115KW |

| Forced Inducted High Boost Gasoline | 165HP | 125KW |

| Normally Aspirated E85 | 140HP | 105KW |

| Forced Inducted Low Boost E85 | 110HP | 80KW |

| Forced Inducted High Boost E85 | 120HP | 90KW |

This is done for increased flow.

Various organisations commonly do this by ‘de-capping’ the injectors. Almost all Bosch EV14 injectors have a cap on the nozzle that is laser welded. This cap controls flow, assisting Bosch in reducing flow variance, and determines spray pattern. A nozzle may have multiple holes drilled on precise angles, to give desired spray pattern, commonly a cone with a particular spray width and angle. By removing this the flow of the injector is significantly increased, which leads to a larger flow variance and reduction in the quality of the spray pattern.

Raceworks injectors are de-capped but are taken one step further, and the remaining single hole/pintle is precisely drilled to restore the spray pattern quality and width.

All Raceworks injectors are statically and dynamically flow matched. This is done to accurately replicate their operating conditions in a vehicle. The n-Heptane test fluid is temperature controlled, and the injectors are preconditioned with 10,000 pulses, before being statically flowed at 3 different fuel pressures. They are then dynamically flowed at the same 3 fuel pressures, but with 25 different pulse widths. The injectors are also flowed at 10 different voltages, from 6V-15V respectively. What is most important is the set of injectors aren’t pulsed at the same time, as is the case with many inferior Injector Flow Benches. Pulsing at the same time causes a pressure differential through the rail and isn’t an accurate representation of their true firing order.